Sure, almost everyone and their dog has heard of plywood, but what is plywood in reality? Plywood is one type of engineered wood. Most people wouldn’t be able to muster more than a simple “it’s a type of wood” response.

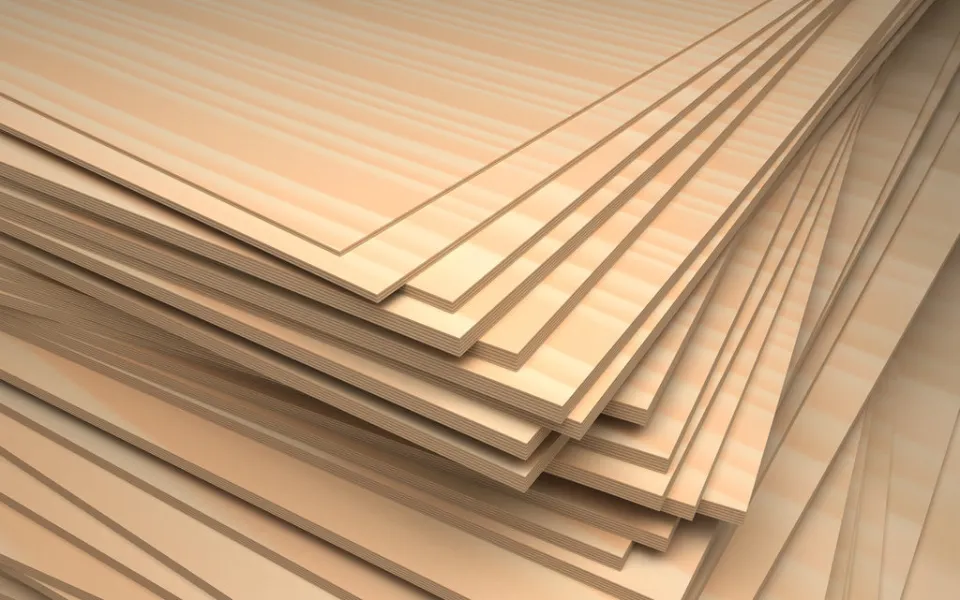

Plywood is a sheet material manufactured from thin layers or ” Plies ” of wood veneer that are glued together with adjacent layers having their wood grains rotated up to 90 degrees to one another. This type of wood is engineered and is a member of the same family as medium-density fiber board (MDF) and particle board (chipboard), which are manufactured boards.

For more specific information, keep reading.

Plywood Basics

The fundamentals of plywood are that it is a sheet material that is given life by joining layers of wood veneer that are glued together. Cross-graining is the process where each adjacent layer is rotated up to 90 degrees. The primary motivation behind this practice is to give the final product extra strength. Cross-graining allows plywood to minimize expansion and shrinkage, increase stability, and resist splitting when fastened at the edges. An odd number of layers will be used when cross-graining. As a result, we have a balanced sheet that won’t easily sag.

The strength of plywood also depends heavily on the core layers. These layers widen the space between the outer layers, where stress is greatest, increasing the material’s capacity to resist bending. By increasing the thickness of the plywood, larger sheets can be produced that can support the same loads. But it’s also ideal for smaller-sized sheets.

Plywood History

Contrary to popular belief, plywood has a much longer history. A long time ago, in 1797, a man by the name of Samuel Bentham, a British Naval engineer, filed patent applications to enable him to make veneers. These patents explained the concept of using glue and several veneer layers to create thicker pieces of wood. This is the first known written description of the item we have come to know and love, and for those at home who are keeping up, it explains the precise steps involved in making plywood.

When the United States of America tasted plywood for the first time in 1865, they quickly started industrial production. Around the same time, artists started using plywood to support their easel paintings instead of the traditional canvases. After 63 years, plywood of the 1.2 x 1.4 meter standard size began to be mass produced for construction purposes.

How is Plywood Made?

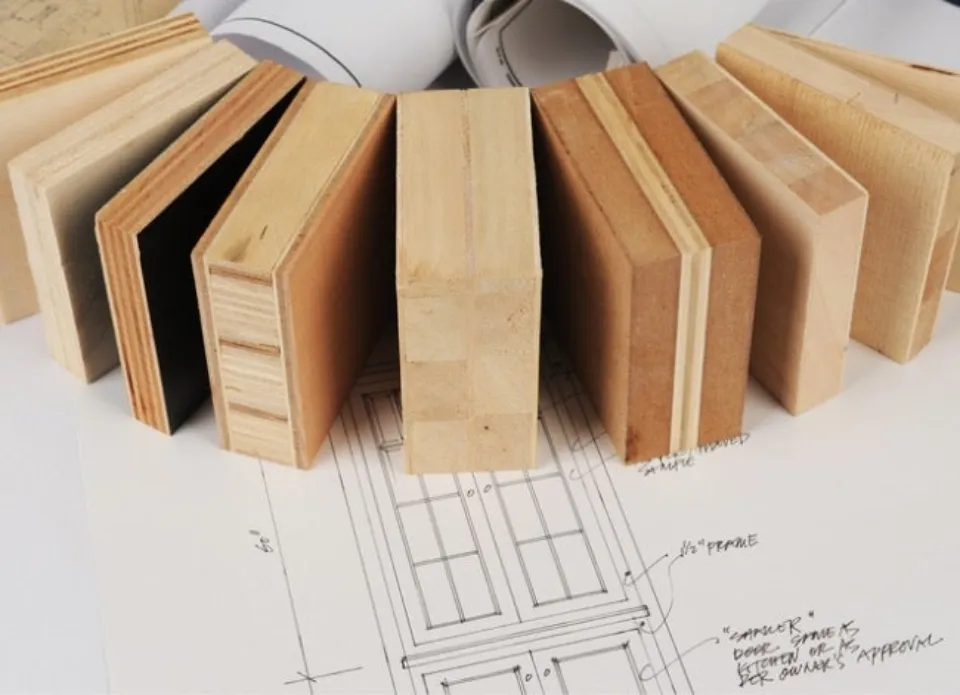

Multiple layers or plys of softwood veneer are used to make plywood panels, and each layer’s grain direction is parallel to the direction of the adjacent layers as they are glued together. These cross-laminated wood veneer sheets are joined by a waterproof phenol-formaldehyde resin adhesive, which is then heated and compressed to cure. In British Columbia, plywood is made from softwood species, typically Douglas-fir, spruce, pine, and fir (collectively known as Canadian softwood plywood, or CSP). Four feet by eight feet is the most typical measurement. Plywood varies in thickness, the most common being ½-inch. There are many options available when it comes to plywood, from smooth, natural surfaces suitable for finish work to more affordable unsanded grades used for sheathing. Over 20 different grades and a dozen common thicknesses are included. In Canada, Graded Douglas-fir Plywood (DFP) is manufactured to meet the requirements of the Canadian Standards Association (CSA) O121 standard, and CSP to CSA O151.

Types of Plywood

The various plywood varieties are listed below.

Softwood Plywood

Spruce-pine-fir, or SPF, is another name for softwood plywood, which is made of spruce, pine, and fir. Though it can be made from cedar (Cedrus sp), douglas fir (Pseudotsugan menziesii). If made from spruce (Picea sp) the prominent grains are coated by a system so that this kind of plywood becomes more effective as hard as concrete and used for shuttering strands and construction.

Hardwood Plywood

Hardwood Plywood is made from angiosperms. Firmness, surface hardness, rigidity, and resistance qualities serve to distinguish this type of plywood. This can be used to bear heavy weight.

Tropical Plywood

This kind of plywood is created by combining various tropical timber types. Although it was previously only collected from the Asian region, it is now also collected from Africa and America.

Aircraft Plywood

Woods from Mahogany (Swietenia Macrophylla), Spruce (Picea sp.), Birch (Betula sp.) are used to make Aircraft Plywood. The African mahogany gives usable structural aircraft plywood. European birch is the best variety of birch tree. Known for its strength, this type. Although this type is also made of mahogany, spruce, and birch, its unique feature is its heat resistance.

Decorative Plywood

Overlaid plywood is a different name for decorative plywood. Usually made from woods of ash ( Fraxinus sp), oak (Quercus sp.), Red oak (Quercus rubra), birch, Maple (Acer sp), mahogany, Dalbergia sisso, also known as Philippine mahogany, is a type of rosewood.

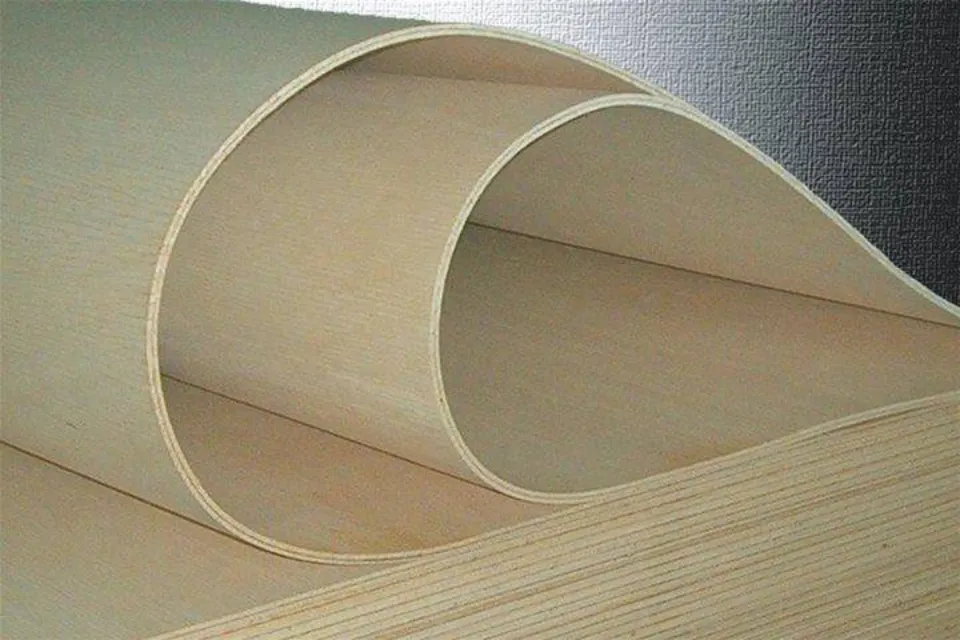

Flexible Plywood

As the name implies, flexible furniture or structures are made from flexible plywood. The majority of the furniture from the eighteenth century had curved structures. These are made from Baltic Birch ( Betula sp).

Marine Plywood

Marine plywood is a category of plywood that can be used in environments with moisture, humidity, or moisture. Even in moist environments, it can be used for extended periods of time. The layers of marine plywood have too small of a core gap, which prevents the wood from holding water inside the gaps. It is also resistant to fungi.

What is Plywood Used For?

A cross-section of wooden sheets joined with their grain directions 90 degrees apart is known as plywood. Resins are used to bind these together. Particle board, chipboard, and MDF (medium density board) are all mixed together. It is made of thin layers of sheets all stuck together.

Some Major Uses of Plywood are:

- It must be used as a high-quality layered wood material if a sturdy material is required.

- It is suitable for the construction and furniture industries because of its resistance to bending, breaking, splitting, and warping.

- It is good for using outdoors.

- The use of it for aviation and space travel dates back to 1939.

- For the shipping industry, low-moisture plywood

- For curved shapes, it bends easily.

Where higher quality, higher strength sheet material is required, plywood is a necessity. It must be impervious to bending, warping, breaking, cracking, and twisting.

Exterior glued plywood is good for outdoor use, but optimal performance happens when the moisture content is low. Plywood’s strength or dimensional characteristics are unaffected by subzero temperatures, making it suitable for some applications. Since World War 2, it has worked out well for the aviation and shipping industries.

Will Plywood Mold Or Rot?

To increase plywood’s resistance to rot or fire, chemical treatments are an option. According to CSA O80 standards, plywood is preserved through a pressure process. Unlike some comparable products, it can withstand some water contact. It will return to its nominal thickness as the wood dries. The effects of fire retardants or any other chemicals must be tested for by plywood manufacturers.

See more:

- Best Engineered Wood Flooring

- Best Engineered Wood Flooring Brands

- How Much Does It Cost to Install Engineered Hardwood Floors?

How Does Plywood Compare to Other Products?

Similar to oriented strand board (OSB), plywood is often a go-to product and is preferred for its many common uses. It offers exceptional durability and lightness. Plywood is more lightweight, stiffer, and water-resistant than OSB. Regardless of their differences, plywood and OSB are comparable products fabricated to meet the same standards of strength and structural performance.

FAQs

Is Plywood Stronger Than Wood?

Since solid wood is a homogenous material, it is stronger than plywood. Since hardwood, which includes teak and Indian rosewood, comes from deciduous trees, it is denser and more substantial than softwood. Softwoods include trees like pine and mango.

What is Plywood Vs Wood?

Plywood is manufactured by gluing wood veneers under pressure to create one board. It is better for cabinets and shelves because it is less expensive and is available in larger sizes than solid wood. Wooden objects are thought to be more distinctive and of higher quality because solid wood is cut straight from the tree and costs more.

How Long Will Plywood Last?

With the advantage of being manufactured 100% from natural plantation wood, plywood has relatively high durability and a lifespan of up to 35 years.

Is Plywood Thick Or Thin?

Generally speaking, plywood is made from 1/8-inch-thick, to more than 1 ½ inches thick. Most plywood in a big box store will be ½ inch, ¾ inch, and 1 inch. In between subflooring and tile, very thin plywood works well as an underlayment.

Summary: What is Plywood?

One of the most popular multi-use engineered wood-based panel products used in Canadian construction projects is plywood. Resin and wood fiber sheets are joined together by plywood to create a composite material that is sold in panels. The face veneers in a typical plywood panel are of higher quality than the core veneers. The purpose of the core layers is to increase the distance between the outer layers where the bending stresses are greatest, increasing resistance to bending forces.

If you have any questions, please leave a comment. My Prime Home tries to give you the best home improvement information. Don’t forget to share the post. Thank you for reading.