There are many different types of engineered wood products that are used to create furniture and other wooden items for both interior and exterior use. One of the many engineered wooden products is particle board. Below will show you what is particle board, how is made, and its types.

The particle wood is comprised of a collection of wood shavings and scraps that are granulated and blended with a resin before being pressed and extruded into a board form. Any byproduct of wood, such as sawdust or wood shavings, that is gathered at a sawmill can be used to create particle board. When compared to plywood, particle board differs due to the way the wood used to make it has been ground into small particles.

Continue reading for more details.

What is a Particle Board?

Almost all construction projects use the well-liked building material particle board. It is widely used in the creation of all kinds of furniture, flooring underlayment, countertops, paneling, and partition structures. The versatility, ease of availability, and low cost of particle boards are helping them become more and more popular. They are sometimes used as an alternative to plywood or medium density fiberboard to lower down the construction cost.

Using waste materials like wood chips, sawdust, and shavings, particle board is an engineered wood product. The wood chips are glued together under heat and pressure to form boards and sheets. It is one of the most environment-friendly materials as it uses waste material effectively. When compared to medium density fiberboard, particle board is less expensive because it is made from waste wood. Also known as chipboard or low-density fiberboard (LDF), it has other names.

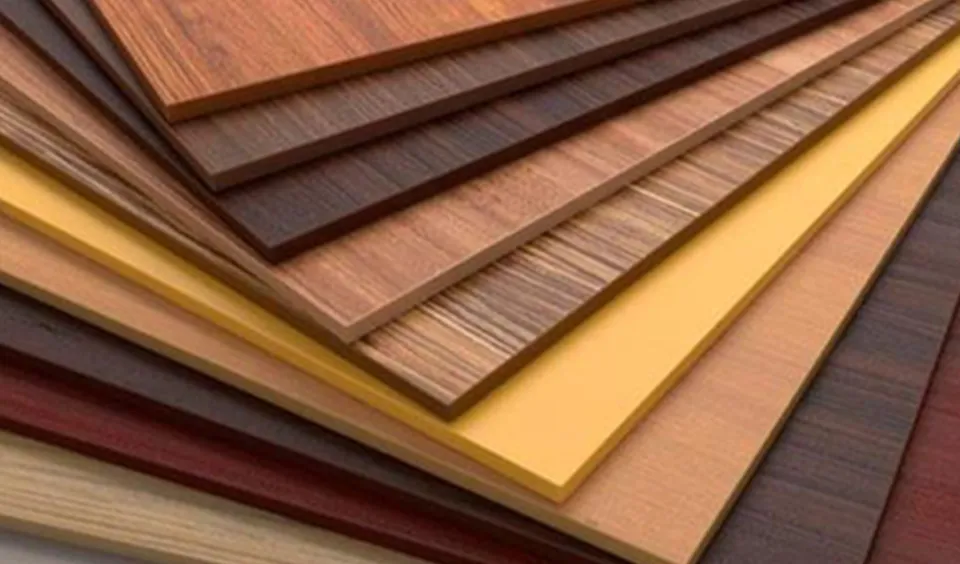

Due to their lower density, particle boards are more likely to warp or break when handled. Furthermore, particle board swells in the presence of moisture, making it less resistant to moisture. With the advent of veneers and laminates, particle boards have become stronger and more durable. Presently, laminated particle boards, which have a layer of laminate fixed to their surface rather than being plain particle boards, are also accessible. This makes the particle boards attractive aesthetically apart from life and strength. When natural wood aesthetics are required along with affordability, veneered particle board is used.

How is Particle Board Made?

It takes a lot of work to create a particle board. It starts by taking wood chips and mixing them together with a resin and moulding it into the shape of a sheet. The disc chipper receives this raw particle board after that. This is a wood chipper that essentially uses several knives mounted upon it as its chipping mechanism. We understand that might sound a little shady, but we assure you that it’s the right approach! This type of wood chipper is used because it tends to result in a more consistent and reliable size for the wood chips. Following drying of these particles, any chips that are too large or too small are thrown away.

A fine mist of resin is then sprayed onto the sheet. At this point in the manufacturing cycle, waxes, dyes, wetting agents, and release agents will be used on the board if a Moisture Resistant variety is being created. While this doesn’t make your Particle Board waterproof, it does give you a product that can easily withstand exposure in damp areas.

After the Particle Board passes through the mist, the chips are layered into what is known as a carpet, which is then separated into “blankets”. These are subsequently compressed in a cold press before being transferred to another press that uses extreme pressure and heat to harden the glue applied to the board. Finally, once everything cools down some trimming and sanding will be done and then it’s off to Plyco!

Different Types of Plywood

Here are the different types of plywood:

Single-layer Particle Board

Wood particles of uniform size are pressed together to create single-layer particle board. A flat, dense board, it cannot be painted but can be veneered or plastic laminated. This kind of particle board is not waterproof, but it is water-resistant. Particle boards with only one layer are appropriate for use inside.

Three-layer Particle Board

A layer of large wood particles is sandwiched between two layers of very small, extremely dense wood particles to create a three-layer particle board. More resin is present in the outer layer than the inner layer. A three-layer particle board’s smooth surface makes it perfect for painting.

Graded-Density Particle Board

A layer of coarse wood particles is sandwiched between two layers of fine wood particles to make a graded-density particle board. Cabinets and other wooden furniture are made using this kind of particle board.

Melamine Particle Board

Particleboard infused with melamine is created by applying a decor paper to the surface of particleboard while under intense heat and pressure. The wood particles in a melamine particle board are bonded using melamine-urea formaldehyde resin and wax emulsion. It is water-resistant because of this. Particle board made of melamine resists scratches. It is available in a wide variety of hues and textures. Applications of melamine particle board include wall paneling, furniture, wall cladding, wardrobes, and modular kitchen.

Cement-bonded Particle Board

Magnesium-based cement or Portland cement is used as the bonding agent in cement-bonded particle board. The composition is 60% cement and 20% wooden particles, including shavings, sawdust, and chips of wood. The remaining 20% is water. This kind of particleboard is resistant to rot, termites, moisture, and fire because it contains cement. They can be used to build false ceilings, walls, and long-lasting covers for concrete floors and walls in buildings situated in high-humidity areas due to their high moisture resistance. They are also used for making fire-resistant furniture products

Veneered Particle Board

A veneered particleboard is one that has a thin veneered wood slice attached to its surface. The veneered particleboard appears like a natural wooden board. Additionally, a veneered particleboard is more resistant to warping than a regular particle board.

Laminated Particle Board

A plain piece of particle board is transformed into laminated particleboard by having a thin laminate sheet adhered to it. Particleboard’s appearance and durability are both enhanced by a laminate sheet.

FAQs

What Are Particle Boards Used For?

Particle board is one of the more ubiquitous wood-based products used in flat-pack furniture and for interior cupboards and work surfaces (finished with Aside from ceiling and floor panels, HPL) is also utilized.

What Are the Disadvantages of Particle Board?

The disadvantages of particle board include its susceptibility to damage, lack of water-resistance, and its incompatibility with drilling (so, cannot handle screws).

Which is Better MDF Or Particle Board?

MDF is fairly stronger than particle-board. Particle board lacks significant strength. Particle-boards are generally less durable than MDF, which is quite durable.

What Are Particle Boards Made Of?

Particle board is manufactured from small wood particles such as sawdust and shavings from the manufacturing of other products, glued together using a resin under heat and pressure.

Summary: What is a Particle Board?

Particle board, also known as chipboard or low-density fiberboard, is an engineered wood product manufactured from wood chips and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is often confused with oriented strand board (OSB, also known as flakeboard, or waferboard), a different type of fiberboard that uses machined wood flakes and offers more strength.

If you have any questions, please leave a comment. My Prime Home tries to give you the best home improvement information. Don’t forget to share the post. Thank you for reading.