What is High-Density Fiberboard? Below will show you how is HDF Manufactured, its features, main uses, and HDF vs MDF.

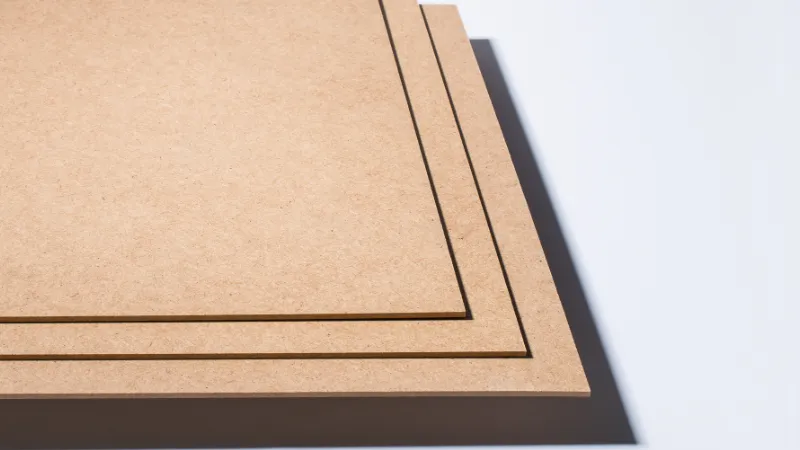

High-Density Fiberboard (HDF) is an engineered wood product created by gluing wood fiber obtained from chips and pulped wood waste under extreme pressure and heat. HDF is a step up from MDF and plywood when it comes to engineered wood.

To learn more, keep reading.

What is HDF?

High-density fiberboard (HDF) is a type of engineered wood product made of pulp wood waste and wood fiber, which are bonded together under high pressure and high temperature. In terms of engineering wood, HDF is an improved version of MDF and plywood.

There is actually a step above HDF. Super-Refined HDF (SRHDF), which is similar to HDF but uses smaller chips and pulped wood waste to produce a stronger and more resilient material, is made from HDF. While HDF and SRHDF share many characteristics with solid wood, they differ from wood in that they lack a grain and are resistant to cracking when temperature and humidity levels change.

How is HDF High-Density Fiberboard Manufactured?

High-Density Fiberboard, also known as HDF, is a type of engineered wood product that is created by hot pressing wood fibers that are extracted from waste chips or wood pulp and binding them into a board at extremely high pressure with the help of synthetic resins and binders. High-density MDF board is another name for this.

Features of High-Density Fiberboard HDF

- Like MDF, high-density MDF board also does not have any grains in cross-section, as it is a composite material with uniform density. In contrast, it is thinner and more dense than MDF and is more compact than MDF.

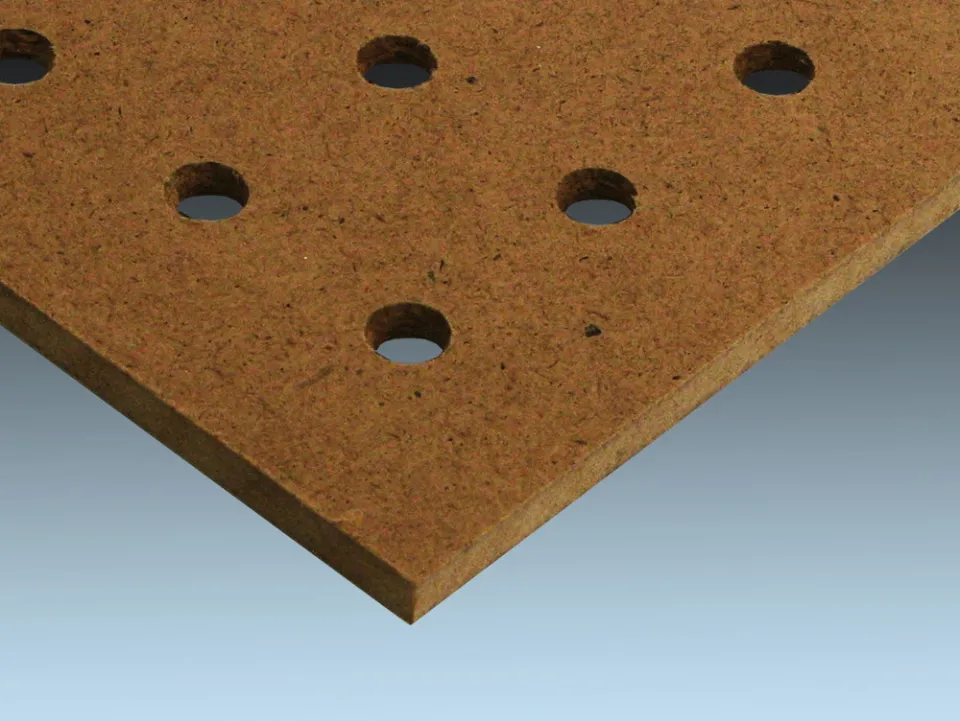

- HDF High-Density Fiberboard is extremely thin because, as its name suggests, it is highly dense. It is, therefore, not suitable for making grooves or moldings.

- Since waste materials like sawdust and wood fibers are used in the production of high-density board wood, it can be said to be “green” or environmentally friendly. However, due to the formaldehyde used as the binding agent, take precautions against toxic gas emissions.

- In order to maintain its dimensions, HDF fiberboard does not contract or expand when heated.

- High-density boards can be finished using veneers, laminates, or paint.

- It needs to be completely covered on all exposed surfaces because it will swell if it comes in contact with water.

- Although more expensive than MDF, HDF fiberboard is significantly more affordable than plywood or solid wood.

Main Uses

Office and high-grade furniture, stereos, wall panels, shelves, and other items are all made of good antistatic flooring materials. The packaging material is excellent as well. Additionally, it can be directly processed into composite flooring, strengthened wood flooring, and other products, replacing high-end hardwood in interior decoration.

HDF Vs MDF

Are you curious how HDF High-Density Fiberboard and MDF are different?

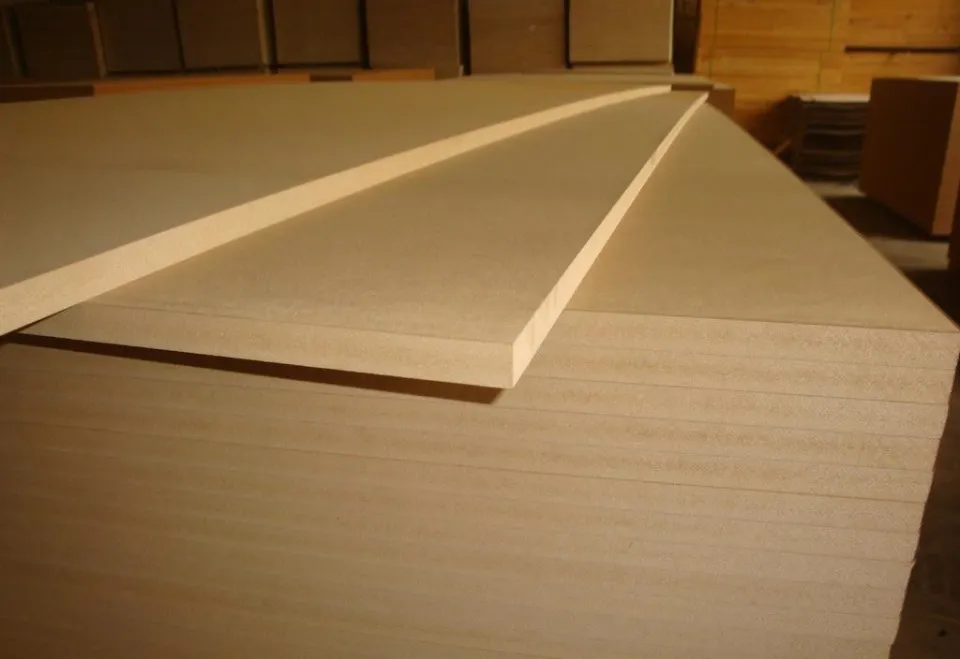

The price isn’t the only factor setting HDF apart from the significantly less expensive MDF, despite the allure of the higher density. Since HDF is much thinner due to its higher density, it cannot be used to make items like skirting boards or interior moldings. While neither version does well around water, HDF is more water-resistant than MDF, and its density does also make it stronger.

Furniture and decorative items are much better suited to MDF, on the other hand. It’s highly affordable, and has a smooth surface that lends itself well to being painted. Another way to give the appearance of solid wood is to use veneer over MDF. Even though it isn’t as strong as HDF, this material is still very robust and won’t change in size in response to heat or humidity. Each type of MDF, such as bendy or ultralite, is best suited for a particular use.

FAQs

Is HDF Better Than MDF?

Similar to MDF, HDF (High Density Fibreboard/Hardboard), also known as HDF wood, is a manufactured composite panel product made from compressed wood fibers. It is a stronger, harder product than MDF with a typical density of up to 900kg/m3.

Is High Density Fiberboard Good?

For cabinet doors, we highly recommend HDF. It’s durable, economical, and extremely versatile for any and all cabinet projects.

What is High Density Fiberboard Made Of?

High Density Fiberboard (HDF) is an engineered wood product composed of wood fiber extracted from chips and pulped wood waste, formed by glue under immense pressure and heat. HDF is an improved version of MDF and plywood when it comes to engineered wood.

Does IKEA Use MDF Or HDF?

IKEA’s cabinets are made out of MDF (MDF stands for Medium Density Fiberboard) wrapped in a very durable melamine finish…

Summary: High-Density Fiberboards

Although HDF might not be the first material that comes to mind when you think of cabinet doors, it is a great substitute for solid wood and may even be the better option for your kitchen project.

If you have any questions, please leave a comment. My Prime Home tries to give you the best home improvement information. Don’t forget to share the post. Thank you for reading.