You ought to be knowledgeable about the various components of your flooring system, including how laminated veneer wood and old growth trees are utilized. Below will give you specific details about floor joists.

Floor joists are structural members that span open spaces horizontally in order to transfer loads to vertical structural members.They are necessary for dispersing live and dead loads to the floors below and eventually down to the ground. Floor joists essentially provide the floor support required to transport people, furniture, and building supplies.

Your building might encounter serious structural problems, such as floor collapse, if it lacks floor joists.

Continue reading to discover more.

What is a Floor Joist?

A floor that extends over an open space is supported by floor joists, which typically make up the upper storey of a house. They are placed equidistant and parallel to one another and span between loadbearing walls or where large open spaces are required below between walls and / or structural beams. It is unlikely that the occupier will ever see them because the upper surface is covered by the walking surface and the lower surface is finished with ceilings in the rooms below.

The load, which is controlled by the use of the upper rooms, will determine the size and frequency of the joists as well as the span between supports. The joists surrounding openings for stairs and/or lifts must be strengthened, and this must be taken into account early on in the design process.

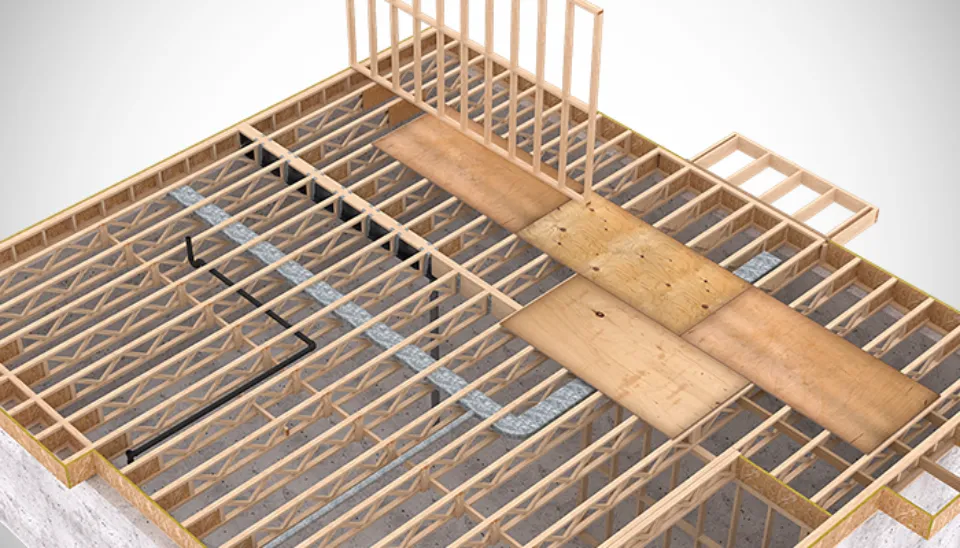

Traditionally floor joists would have been formed of solid timber and it is noticeable in older properties that the floor becomes uneven as the timber dries out resulting in shrinkage and warping of the joist. As the floor boards bump up against the fixing nails, this will cause squeaks. In modern day properties the floor joists will be of Engineered Timber; either I-joists consisting of softwood flanges with a sheet material web, or metal-web joists where again the softwood flanges are connected, as the name suggests, with metal webs. Due to the fact that both of these products significantly reduce the amount of solid wood used, there is almost no shrinkage and consequently a quieter floor.

Electrical and plumbing services are typically hidden in the space between the walking surface and the ceiling finish between the joists. These need careful planning because, while service runs that are parallel to the joists do not pose a problem, runs that are perpendicular will require holes in the joists, which will obviously weaken them. Metal web joists however have ample space between the webs to accommodate the majority of service runs and particularly come into their own when ducting for heating, ventilation and air conditioning is installed.

What is Floor Joist Spacing?

Most joists are placed 16 inches on center, however, they can be spaced anywhere from 12-24 inches apart.

So how do you establish the ideal floor joist spacing?

Structural engineers are responsible for deciding the proper spacing for a building project. They perform calculations to arrive at this conclusion. When determining the ideal joist spacing, experts will take into account things like how much live and dead weight the floor must support.

Most floors must be capable of supporting a live load of 40 pounds per square foot and a dead load of 15 pounds per square foot. Structural engineers will use these numbers to calculate existing loads and then perform additional calculations to size the joists (considering factors like lumber type/species/size) and appropriate joist spacing.

Types of Floor Joists

There are three types of floor joists used by contractors in wooden structures.

Solid Lumber

Douglas fir is one of the wood types utilized for floor joists. When using regular wood as opposed to specialty wood, solid lumber floor joists are the least expensive option. However, compared to other materials, solid lumber is generally more water- and fire-resistant.

The most common kind of floor joist is solid lumber because of its affordability and wide range of options. The most basic kind of floor joist, it is simple to use and comprehend. You can’t mess it up if you know anything about construction.

I-Beams

I-beams have an I-like shape. The center of the I is made of plywood or OSB, while the top and bottom are made of solid wood or laminated veneer. In comparison to solid lumber, they have a greater span capacity.

They can be more affordable than other options due to the use of plywood, and because it can be stacked and glued, a stronger board can be made than one made of just one layer of plywood. I-joists become very sturdy as a result.

Floor Trusses

Floor trusses are made with 2×4 wood planks on the top and bottom with a “web” of diagonal boards in the middle. Metallic plates in the floor trusses hold the boards in place. They use less wood than usual thanks to their design.

Floor trusses also have gaps that leave room to make wiring and plumbing much easier. Crawlspaces are trickier with web floors, though, as there isn’t as much room as there would be with solid wood.

Parts of a Framed Floor System

A framed floor system consists of:

- Wood Plate: A plate is a piece of wood that is bolted to the top of a concrete foundation wall or nailed to the top of a wood wall. Because it is made of wood, the plate can be nailed to the floor joist.

- Floor Joist: The floor joist spans the open space under the floor and is fastened to the plate material with nails.

- Floor Sheeting:The floor sheeting is usually made from 3/4″ or thicker sheets of plywood or The floor sheeting is also engineered to offer a solid floor, similar to OSB. The floor sheeting must be nailed with the proper size nails, spaced according to the engineers’ instructions.

- Rim Joist:On the ends of the joists a board is run perpendicular to the floor joists. Rim joists are what this board is known as. It supports the joists and carries the weight of the wall and roof along the house’s edge.

- Beams and hangers are examples of optional floor system components. These are only utilized when the house and floor’s design calls for it.

step 5 Mechanical Equipment In Joists

The spaces between the joists are frequently home to mechanical equipment. As a result, the ceiling above the floor joists remains higher. The amount of the webbing between the top and bottom that can be removed without compromising strength is determined by engineering. Most of the time, it is not acceptable to remove material from the joist close to its ends, but it is acceptable to remove some material from the span’s middle.

Load-Bearing Floor Joists

Floor joists are designed to be load-bearing. They serve as the foundation for higher levels and frequently transfer weight to vertical supports within the foundation. Floor joists support the walls in upper levels.

Supporting Structures

The following floor is supported by walls. A wall is not load-bearing if it is erected parallel to the joists. Only walls erected perpendicular to the floor joists are capable of supporting weight. Go here for more information on load-bearing walls.

Supportive Framework

What you need to know is floor joists bear the weight of the entire home. While walls usually only bear part of the weight, with some not bearing any weight at all. Floor joists are important for this reason alone.

Load Capacity

You must ascertain the floor trusses’ load carrying capacity. The live load in residential home floors is typically 30 to 40 pounds per square foot (psf), though this varies depending on where in your home it is. First-floor live loads have higher requirements than second-floor live loads

How to Choose the Best Boards for Floor Joists?

Given their significance, selecting floor joist boards for an open web floor can be challenging. You need to know the differences between high bending strength and medium bending strength, for example.

Wood Type

Various wood species have distinctive qualities. While others are stronger, some are more flexible. Most of the time, slow growing trees, like the Douglas fir, are stronger. Fast-growing trees, however, have soft wood.

For floor joists, stronger trees with good elasticity, like Ponderosa pine, are best. Fir, spruce, and pine are a few of the frequently used options. These hardwoods, which you’ll notice are conifers, are excellent choices and simple to locate.

Wood Grade

Lower grades of wood are less structurally sound because they tend to have more flaws. The better the wood will be, then, the lower the number. The higher the grade of lumber, the fewer flaws there are. Lower grade lumber, on the other hand, has a shorter lifespan.

For most projects, including installing floor joists, Grade-2 is perfect, so Grade-1 is not required. Use Grade 3 or higher sparingly because doing so puts your foundation’s integrity at risk.

Both Eastern white pine and Western red cedar have low bending strengths.

Wood Size

Avoid using any boards smaller than a 2 x 6 when it comes to size. The largest size that you will use is a 2 x 12, but the most typical sizes are 2 x 8 and 2 x 10. Despite being a popular option, 2 x 6s aren’t the most affordable.

In contrast to 2 x 12, which can be placed 24 inches apart, 2 x 6 must be placed closer together, which would be less than 16 inches.

How Far They Can Span?

The distance between the supports is called the “joist span”. A few feet to over 20 feet is the range of their span. The span is determined by several factors:

- Engineering for joists: Each manufacturer has engineering for all of its joist products. The tables take into account the desired floor strength, joist length, depth, and spacing.

- The joist’s depth is measured from top to bottom when the joist is standing on its long side.

- The joist span is the distance between the two supports, and its length is that distance. The longer the span the weaker the joist will be

- Joist spacing: This is just a fancy way of saying how close the joists are installed to one another. The strength of the floor system will increase with their installation proximity. Typical spacing is 16 inches on center but they can be spaced as much as 19.2 inches on center and as close as 12 inches on center.

- Floor sturdiness: Standard floors come in a variety of ratings. The ratings for floor systems are rated by how far they “deflect” or sag when typical weight is put on them. On the engineering charts are also the strength ratings.

How They Bear Weight at the Ends?

The ends of floor joists must be supported because they are perpendicular to the bearing walls. The width of the joist is typically the minimum requirement for bearing. A joist can be supported at its ends in a variety of ways.

Bearing on a Sole Plate: A sole plate is a wooden support that is nailed to the bottom of a concrete foundation. The wood plate is simply placed on top of the joist. It has nails holding it to the plate. The quantity and size of nails to be used at the ends are determined by specific engineering.

Bearing on a center wall: When joists span great distances between two foundation walls they are supported in the center on a “bearing wall”.

Regarding a joist hanger, these are just straightforward metal straps that hold the ends. When connecting a joist to a beam, such as over a basement doorway or to keep a room open, they are frequently used. The size and number of nails needed to secure a hanger to a beam will be determined by the engineering calculations included with the hanger.

FAQs

Where to Buy Floor Joists?

Most lumber yards, private businesses, and home improvement retailers like Home Depot all sell floor joists.

The majority of contractors have preferred vendors. But if you’re looking, just do some research. To find out what’s available, browse a few websites.

Can You Use Lvl for Floor Joists

When heavy loads are present, LVL floor joists can be used. They are very expensive but stronger than most other floor joist systems. They could be used in situations where a very stiff floor is necessary or a long span needs to be achieved. Again, because of the expense, it’s not always the preferred option.

Note: LVL, which stands for laminated veneer lumber, resembles plywood somewhat. The main difference between plywood and LVL is the grain of the engineered wood; plywood changes grain direction with each layer while LVL keeps the grain direction the same.

Can I Remove Floor Joist Cross Bracing?

Technically, yes, you can remove floor joist cross bracing. However, structural engineers generally do not advise it.

The purpose of floor joist cross bracing is to stop lateral movement of the joist. The likelihood of lateral movement increasing significantly if they are removed. This is not ideal for obvious reasons.

You may be wondering why one would want to remove floor joist cross bracing in the first place.

Typically, a homeowner wants to make room for HVAC or plumbing.

If an HVAC duct is being installed, an engineer might advise you it’s okay to remove cross bracing. The HVAC duct may prevent lateral movement in the joist by acting similarly to cross bracing.

If you want to remove the cross bracing from the floor joists for any other reason, consult an engineer first.

What Happens If a Floor Joist Breaks?

A floor that bounces or sags indicates a broken floor joist. Additionally, you’ll hear a lot of squeaking noises.

Summary: What is a Floor Joist?

basement, crawl space or lower floor level or between shed floor beams. It resembles a tiny bridge that is only held up at either end. When many joists are installed next to each other and a sub-floor sheeting like plywood or Oriented Strand Board, (OSB), is nailed on top they create a large floor area called a “floor system”.

They are primarily employed in the construction of homes and small offices. They are fairly inexpensive, between $1.00 to $2.00 per lineal foot, for the benefit they provide. This article answers the questions of What Are Floor Joists and What Is A Floor Joist by by describing their uses, how they are made and the types of applications they are used for.

If you have any questions, please leave a comment. My Prime Home tries to give you the best home improvement information. Don’t forget to share the post. Thank you for reading.

Read about